Polishing machines have revolutionized the way we transform surfaces, providing a level of precision and efficiency that was once unimaginable. From automotive restoration to jewelry making, these machines have become indispensable tools in various industries. In this article, we will explore the key features and benefits of polishing machines, highlighting their versatility and impact on different applications.

Enhancing Surface Finishes:

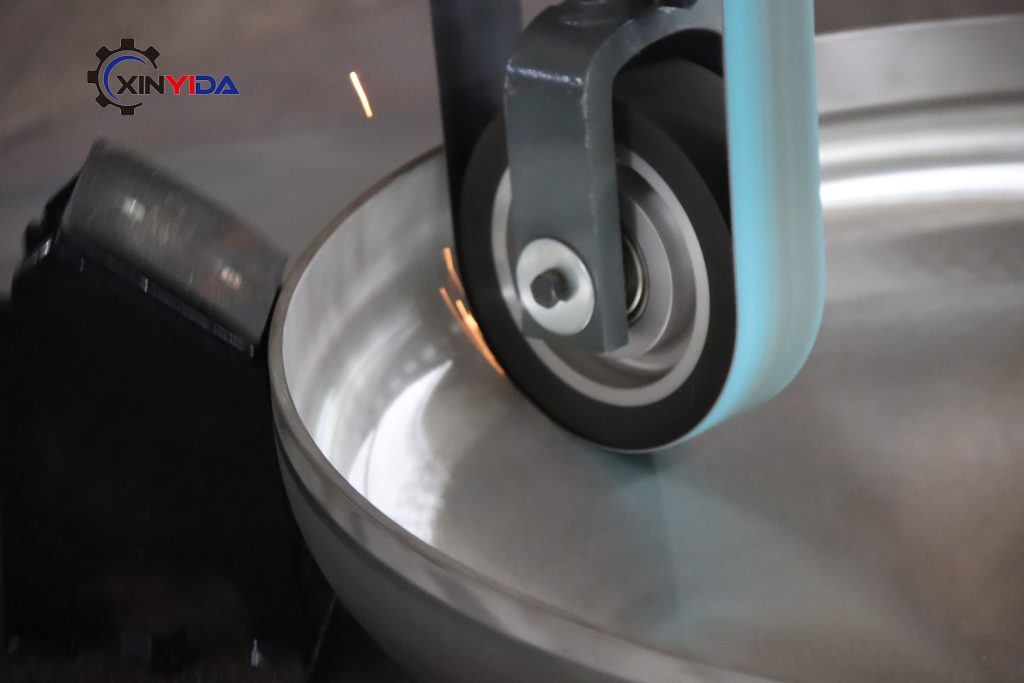

Polishing machines are designed to enhance the surface finish of various materials. Whether it’s metal, glass, wood, or plastic, these machines utilize different techniques to remove imperfections, scratches, and blemishes, resulting in a smooth and glossy finish. The adjustable speed settings and interchangeable polishing pads allow for precise control, ensuring optimal results for different materials and surface types.

Time and Cost Efficiency:

One of the significant advantages of polishing machines is their ability to save time and reduce costs. Compared to manual polishing, which can be labor-intensive and time-consuming, these machines automate the process, significantly increasing productivity. With their powerful motors and advanced polishing mechanisms, they can achieve consistent results in a fraction of the time, allowing businesses to meet deadlines and fulfill customer demands more efficiently.

Versatility and Adaptability:

Polishing machines come in various types and sizes, catering to different applications. From handheld rotary polishers to larger floor-standing models, there is a machine suitable for every task. Additionally, these machines often have interchangeable accessories and polishing pads, allowing users to adapt to different surfaces and achieve the desired finish. This versatility makes them valuable assets in industries such as automotive, aerospace, jewelry, and even household cleaning.

Precision and Control:

Accuracy and control are crucial when it comes to polishing delicate or intricate surfaces. Polishing machines offer precise speed control, enabling users to adjust the RPM (revolutions per minute) according to the specific requirements of the material being polished. This level of control ensures that the surface is treated gently and avoids any potential damage. Furthermore, some machines feature advanced technologies like variable oscillation patterns or automated pressure adjustment, further enhancing the precision and consistency of the polishing process.

Safety and Ergonomics:

Modern polishing machines prioritize user safety and ergonomics. They are equipped with features such as rubberized handles for a comfortable grip, vibration dampening mechanisms to reduce operator fatigue, and safety guards to protect against debris or accidental contact with rotating parts. These safety features not only ensure a safer working environment but also contribute to the overall efficiency and longevity of the machine.

Polishing machines have become indispensable tools in various industries, offering unparalleled precision, efficiency, and versatility. With their ability to enhance surface finishes, save time and costs, and provide precise control, these machines have transformed the way we approach surface treatment. Whether it’s restoring the shine of a classic car or perfecting the luster of a piece of jewelry, polishing machines continue to play a vital role in achieving impeccable results in countless applications.