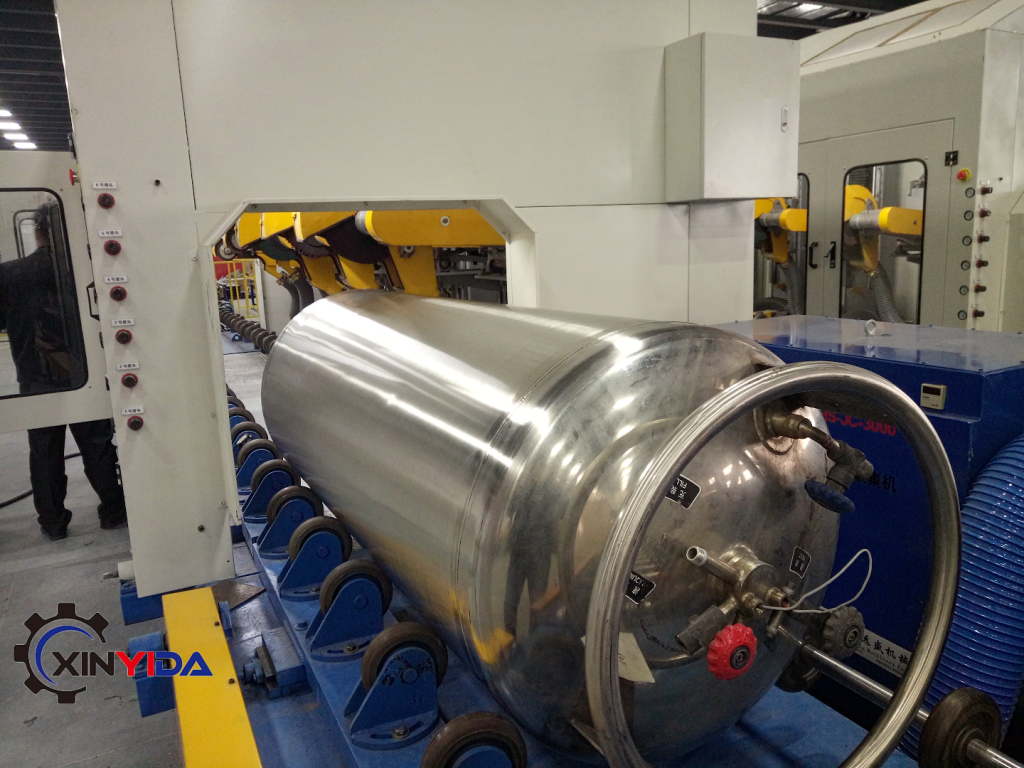

Liquefied natural gas (LNG) is a clean and efficient fuel that is widely used in various industries, such as power generation, transportation, and heating. However, LNG requires special storage and transportation equipment, such as LNG air tanks, which are cylindrical containers that store LNG under high pressure and low temperature.

LNG air tanks need to have smooth and shiny surfaces to prevent corrosion, leakage, and heat loss. Therefore, polishing is an essential process for LNG air tank manufacturing and maintenance. Polishing can improve the appearance, quality, and performance of LNG air tanks by removing surface defects, enhancing surface roughness, and increasing surface reflectivity.

However, traditional polishing methods are manual, labor-intensive, time-consuming, and inconsistent. Manual polishing relies on the skills and experience of workers, which can vary greatly from person to person. Manual polishing also poses safety risks for workers who are exposed to dust, noise, and vibration.

To overcome these challenges, automated LNG air tank polishing with a CNC system has been developed and applied in recent years. CNC system is a computerized numerical control system that can control the movement and operation of polishing machines according to pre-programmed instructions. Automated LNG air tank polishing with a CNC system has many advantages over manual polishing, such as:

– It can achieve high precision, consistency, and efficiency by using advanced sensors, algorithms, and feedback mechanisms.

– It can adapt to different sizes, shapes, and types of LNG air tanks by using adjustable and interchangeable polishing tools and fixtures.

– It can reduce labor costs, human errors, and safety hazards by replacing manual labor with automated machines.

– It can improve environmental protection and energy saving by using dust collection systems, noise reduction devices, and energy-efficient motors.

Automated LNG air tank polishing with a CNC system is the future trend of LNG air tank production and maintenance. It can improve the quality and performance of LNG air tanks while reducing the time and cost of polishing. It can also enhance the competitiveness and profitability of LNG air tank manufacturers and service providers.